LB-Co Extrusion ABA PPR iav-fiber Yeeb Nkab Extrusion Kab

Co-extrusion yog xa ob los yog ntau tshaj molten raw cov ntaub ntawv los ntawm ib tug tuag thiab ua ib tug multi-txheej yeeb nkab uas yuav muaj ntau yam xim los yog phab ntsa thickness. Thaum ntau cov yas sib xyaw ua ke, qhov tshwm sim tuaj yeem ua rau cov khoom sib txawv ntawm cov khoom siv ib leeg. Multi-txheej txheej extrusion tau qhib rau pem hauv ntej tshiab hauv cov khoom siv engineering thiab hais txog ntau qhov kev tsim khoom nyuaj yav dhau los. Co-extrusion tseem tuaj yeem txo cov nqi los ntawm kev siv cov khoom siv rov ua dua tshiab thiab rov ua dua tshiab hauv cov khoom siv nkauj xwb rau tes tuav, laj kab thiab lwm yam kev siv. Cov txheej txheem tuaj yeem pom nyob rau hauv tej yaam num muaj ntau haiv neeg xws li cov yeeb nkab thiab cov khoom siv los yog cov khoom ntim cua tshuab.

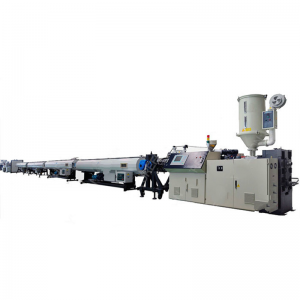

Cov kab uas hla (mm) 50,75,90,110,160 75,90,110,160,200,250

Extruder (rau nruab nrab txheej) 65/132 80/156

Extruder (rau txheej sab hauv & sab hauv) 65/132 lossis 55/120 65/132

Qhov ntev ntawm lub tshuab nqus tsev vacuum (mm) 6000 6000

Haul-offs tshuab 3claw 3claw

Txiav tshuab planetary txiav planetary txiav

Cov kab tiav Extrusion yog tsim los ntawm cov khoom hauv qab no:

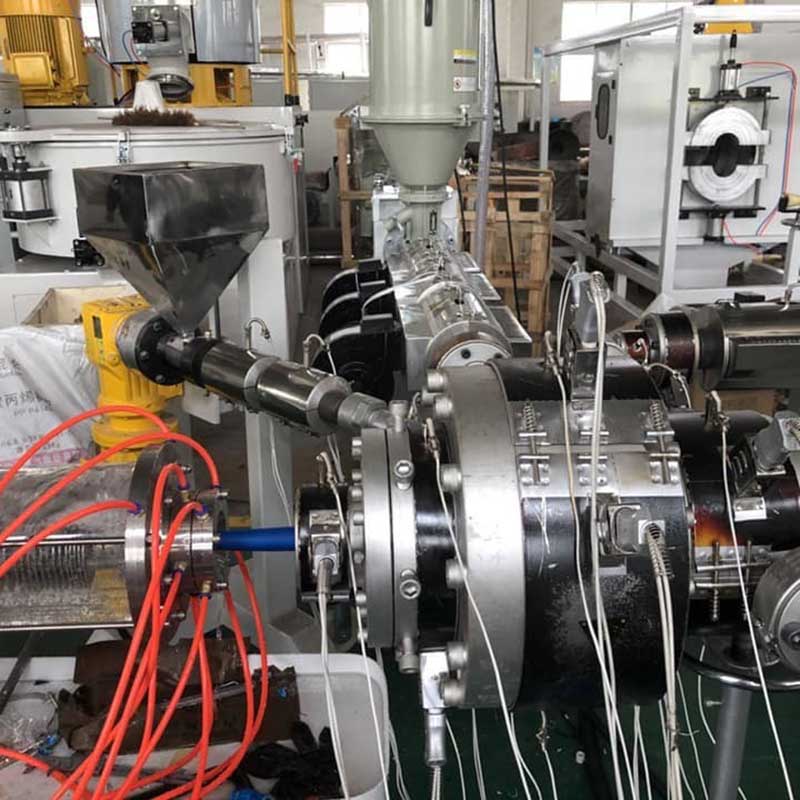

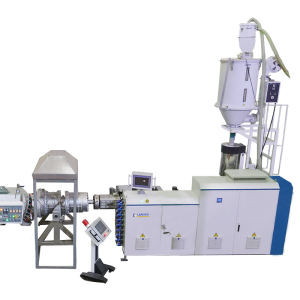

1. Ib leeg ntsia hlau extruder

2.Co- extruder: kev tsim cov cim kab ntawm cov yeeb nkab lossis ntau txheej ntawm cov kav dej

3. Tuag taub hau

4.Nqus tank: vim txoj kab uas hla, nws tuaj yeem tsim ib leeg, ob chav nqus tsev vacuum

5.Cooling tank: vim txoj kab uas hla, cov lej ntawm lub tank txias tuaj yeem yog ib, ob lossis peb

6.Haul-offs: vim txoj kab uas hla, nws tuaj yeem tsim ob, peb, plaub, rau, yim, kaum, kaum ob kab ntsig

7.Cutter: vim txoj kab uas hla, nws tuaj yeem tsim los ntawm tsis muaj cov khoom txiav los yog lub ntiaj teb cutter.

8.Coiler/Tipping chute