LB-Co-extrusion ob txheej wpc profile extrusion kab

Raw khoom + ntoo zog + additive → mixing → granulating → conical twin-screw extruder → profile extrusion pwm → txias molding tuag → nqus calibration txhawb → thauj-tawm → cutter → khib → khoom tiav

1> Conical Ob chav ntsia hlau extruder: SJSZ-65/132

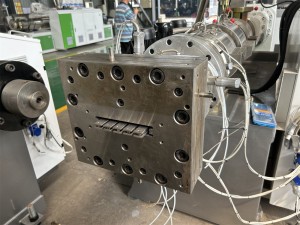

2> WPC PP / PE / PVC qhov rais, qhov rooj, laj kab, decking, skirting, pem teb profile pwm

3> Nqus calibrating system

4> Haul tawm tshuab

5> Txiav tshuab

6> Tshem tawm txoj hlua khi

7> Mixer

8> Embossing tshuab

| Extruder qauv | SJZ55/110 | SJZ65/132 | SJZ80/156 | SJZ92/188 | ||

| Lub cev muaj zog (kw) | 22 | 37 | 55 | 110 | ||

| Khoom dav | 200 | 240 | 300 | 600 | 900 | 1200 |

| Lub tshuab nqus tsev zog | 4kwx 1 | 5.5kwx 1 | 5.5kwx 1 | 5.5kwx 2 | 1 7.5kwX1 | 1 7.5kwX1 |

| twj tso kua mis | 2.2 kwm | 2.2 kwm | 4 kwv | 5 kws | 7,5 kwv | 7,5 kwv |

| Hauling ceev | 0-5m / min | 0-5m / min | 0-5m / min | 0-3m / min | 0-2.5m / min | 0-2.5m / min |

| Peev xwm (kg / h) | 70kg / h | 110kg / h | 110kg / h | 170kg / h | 300kg / h | 300kg / h |

| Net Nyhav (kg) | 3000 | 5000 | 6500 ib | |||

Yog tias cov khoom siv raw yog PE lossis PP, koj xav tau cov hmoov ntoo + PP / PE cov khoom sib xyaw ua ke, thiab tom qab ntawd muab tso rau hauv pelletizing kab, thaum kawg tau txais cov ntoo yas pellets kawg.