LB-PVC Electrical Conduit ntau lawm kab

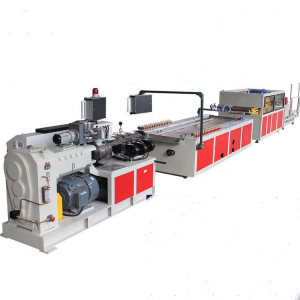

LB Machinery PVC Hluav Taws Xob Conduit Ntau Lawm Kab

LB Machinery muaj cov kab ntau lawm rau pvc hluav taws xob conduit xws li 16mm (0.5inch) txog 50mm (1.5 nti). Peb cov extruder, zoo li tag nrho cov tshuab yog crafted nrog cov khoom lag luam sab saum toj kom ntseeg tau tias kev ruaj ntseg ntau lawm, kev ua tau zoo thiab lub tshuab ua haujlwm ntev. Peb conical ntxaib ntsia hlau extruder tsim cater rau cov ntaub ntawv raw khoom kom ntseeg tau tias homogeneous sib tov, zoo dua plastification thiab conveying efficiency. Tag nrho cov tswj kub yuav yog OMRON thiab tag nrho cov khoom hluav taws xob yuav yog Siemens lossis Schneider. Peb muab cov kev daws teeb meem customized tailed rau ntau yam kev xav tau.

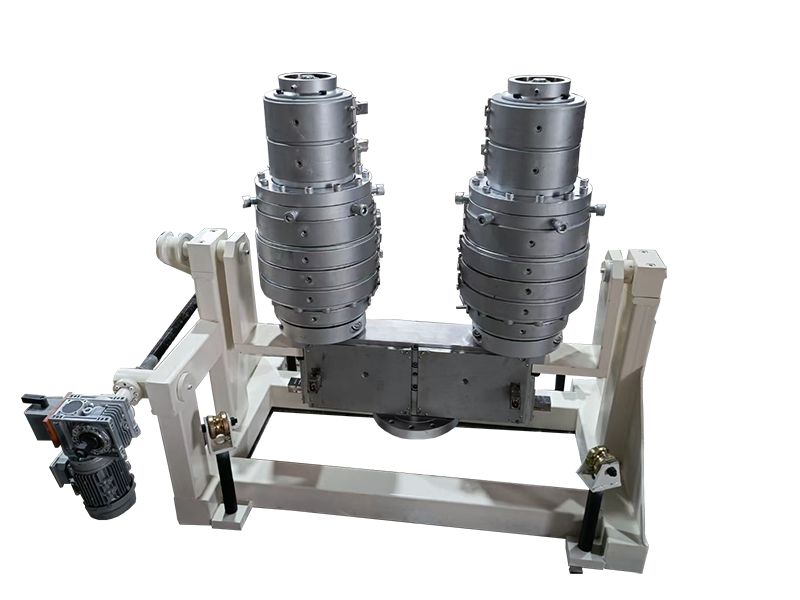

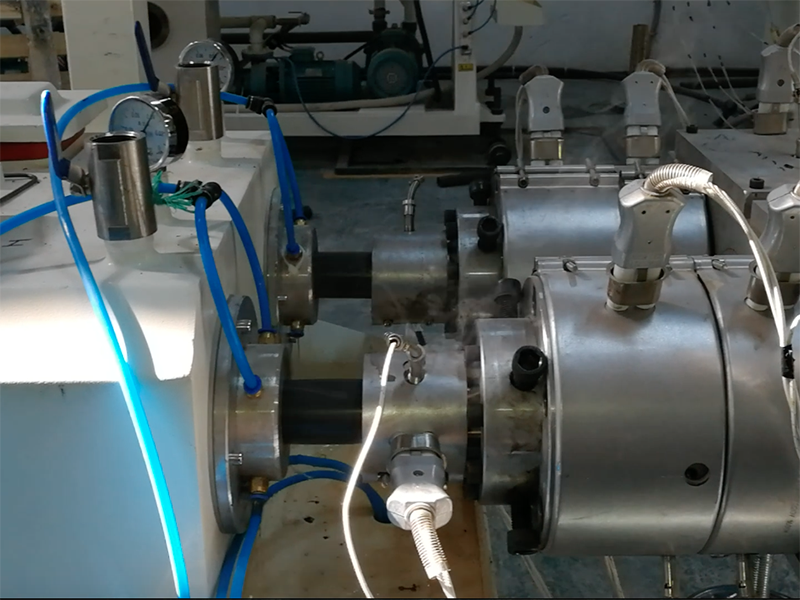

➢ Twin ntsia hlau extruder tshuab

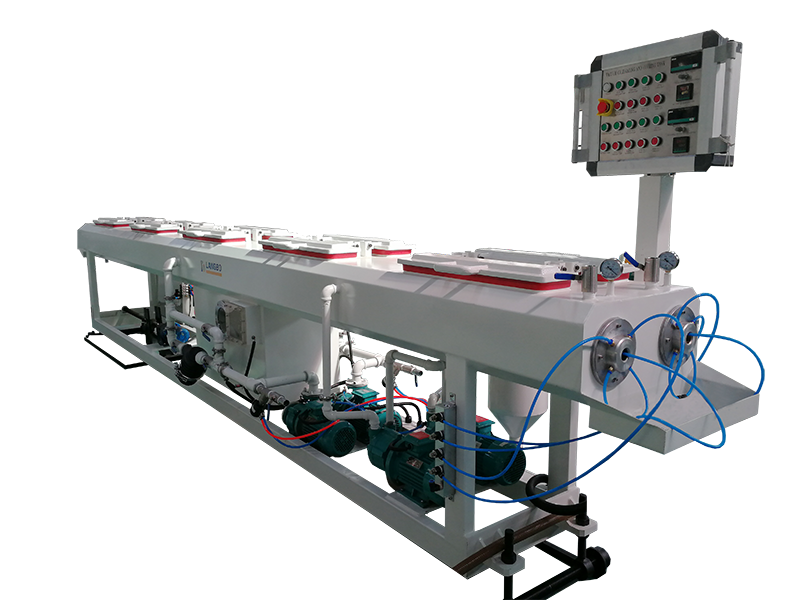

➢ Lub tshuab nqus tsev & txias tank

➢ Haul off (ruber) tshuab

➢ Cutter tshuab

➢ Tipping rooj

➢ Sib tov

Muaj ob hom khoom siv raw rau kev tsim cov yeeb nkab PVC.

a). PVC resin thiab lwm yam khoom ntxiv tuaj yeem yuav thiab sib xyaw ua ke los ntawm cov neeg siv khoom lawv tus kheej raws li cov qauv. Hauv qhov xwm txheej no, cov Mixers yuav tsim nyog nruab nrog cov kab extrusion.

b). Yog hais tias cov neeg muas zaub yuav npaj PVC granules rau ua yeeb nkab los ntawm lwm tus kws tshaj lij ntawm PVC granules, cov Mixers yuav tsis tsim nyog.

➢ Tswb tshuab

Nws nyob ntawm kev xav tau los ntawm kev ua lag luam. Yog tias cov neeg siv khoom xav tau cov yeeb nkab nrog lub qhov (socket). Lub tshuab Belling yuav tsim nyog.

110mm pwm

Lub tshuab nqus tsev tank

Extruder

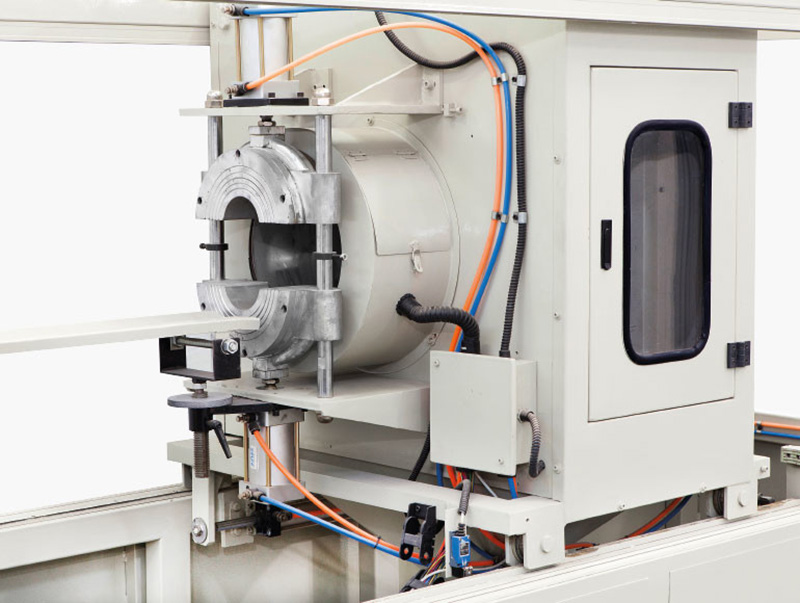

Daim ntawv shaping tshuab

Haul-off thiab txiav unit

Tswb tshuab

Ob chav strand extruder

Vim li cas thiaj xaiv LB tshuab?

➢Los ntawm extruder mus rau tag nrho cov kab ntau lawm, peb muab cov tshuab ua haujlwm zoo thiab cov chav nyob ib leeg lav kev ua haujlwm ntev thiab ua haujlwm.

➢ Peb lub tuam tsev R & D tau mob siab rau nrhiav txoj hauv kev zoo dua qub kom txuag tau lub zog thiab tau txais txiaj ntsig siab tshaj plaws.

➢ Lub sijhawm pabcuam tuav lub hom phiaj tseem ceeb ntawm kev lav phib xaub rau txhua tus neeg siv khoom muab cov ntaub ntawv qhia txog lub sijhawm los ntawm kev txiav txim kom xa cov tshuab.

| Qauv | 50B | 50C ua | 63B ib |

| Cov kav dej ntau (mm) | 16-50 | 16-50 | 16-63 : kuv |

| Ntsia Hlau Qauv | 51/105 ib | 65/132 ib | 65/132 ib |

| Ntau lawm ceev (m / min) | 10 × 2 | 12 × 2 | 12 × 2 |