LB-PVC phab ntsa vaj huam sib luag Extrusion kab

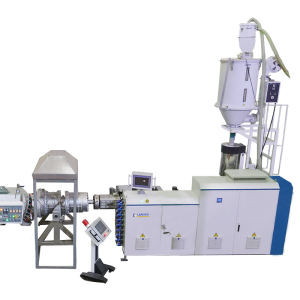

LB Machinery PVC Phab Ntsa Vaj Huam Sib Luag Extrusion Kab

LB Machinery muaj cov kab tiav extrusion rau pvc phab ntsa vaj huam sib luag raws li cov duab kos ntawm cov neeg siv khoom. Peb phab ntsa vaj huam sib luag extrusion pwm yog tsim thiab tswj los ntawm cov kws paub txog kev ua raws li lub teb chaws tus qauv. Peb cov phab ntsa vaj huam sib luag dav dav cabling-tawm faib foob pob hluav taws caj npab muab kev tsav tsheb txaus thiab txav ceev. Lub saw cutter yog tswj los ntawm PLC humanized tshuab thiab ua haujlwm yooj yim dua. Peb muab cov khoom lag luam saum toj kawg nkaus rau cov khoom lag luam kom ntseeg tau cov kav ntev thiab tsim khoom.

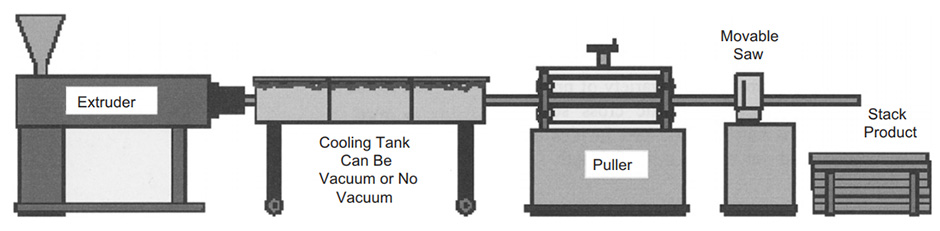

➢ Sib tov

PVC resin thiab lwm yam khoom ntxiv tuaj yeem yuav thiab sib xyaw ua ke los ntawm cov neeg siv khoom lawv tus kheej raws li cov qauv thiab daim ntawv thov. Rau cov phab ntsa vaj huam sib luag ntau lawm (PVC profile), cov khoom sib tov zoo yog qhov tsim nyog thiab qhov tseem ceeb.

➢ Conical ntxaib ntsia hlau extruder tshuab

Vim lub cua sov rhiab heev feature ntawm PVC, peb txais yuav high-zoo conical twin ntsia hlau. Hauv kev ua, kev sib hloov thiab plasticizing yog temper thiab precision.

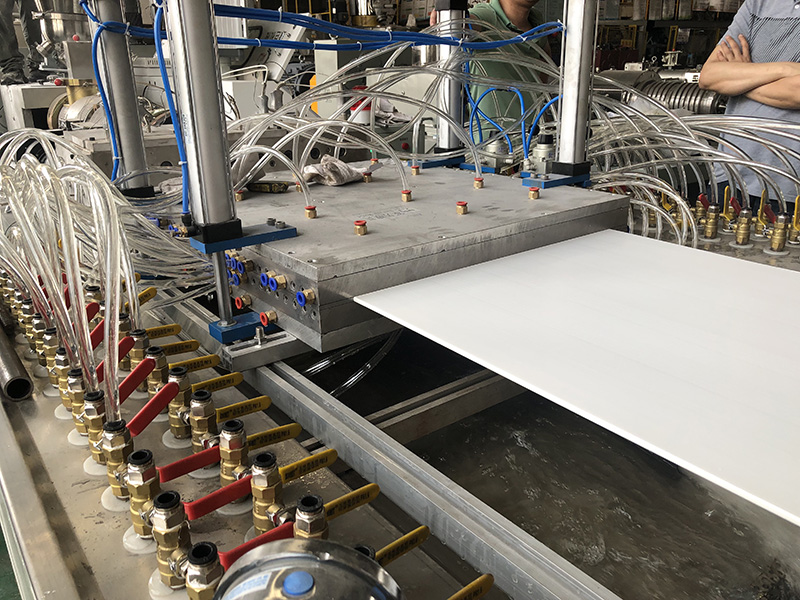

➢ Calibration rooj

Peb muab 8-12m calibration rooj kom txaus txias thiab solidification. Kaum ob lub tshuab nqus dej tsis tu ncua rau ntawm phab ntsa vaj huam sib luag profile.

➢ Haul off (ruber) tshuab

Peb cov phab ntsa vaj huam sib luag dav dav cabling-tawm faib foob pob hluav taws caj npab muab kev tsav tsheb txaus thiab txav ceev.

➢ Cutter tshuab

Lub saw cutter yog tswj los ntawm PLC humanized tshuab thiab ua haujlwm yooj yim dua.

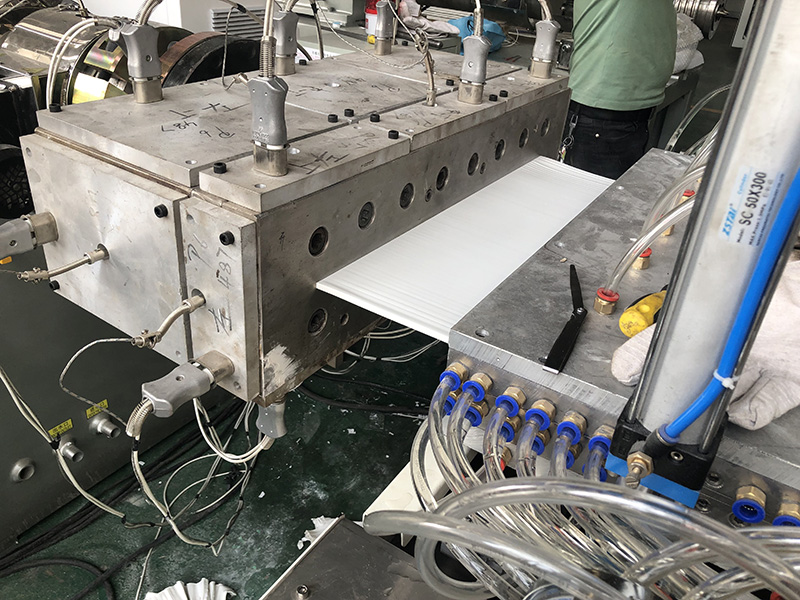

➢ Extrusion txheej thiab lamination

Lub tshuab extrusion lamination yog siv los txheej rau ntawm phab ntsa vaj huam sib luag profile. Tom qab ua tiav, lub vaj huam sib luag yuav muaj qhov zoo-zoo thiab hnav-tiv taus zoo ib yam rau ntau daim ntawv thov.

Txiav unit

Hnyav-off unit

Laminator

Profile pwm

Profile nqus tank

Cov khoom siv dav dav

Vim li cas thiaj xaiv LB tshuab?

➢ Peb tsom mus rau cov ntsiab lus thiab txhim khu kev qha ntau lawm technology, lub tshuab tsim raws li cov khoom siv cog thiab cov kev xav tau ntawm tus kheej.

➢ Peb lub tuam tsev R & D tau mob siab rau nrhiav txoj hauv kev zoo dua qub kom txuag tau lub zog thiab tau txais txiaj ntsig siab tshaj plaws.

➢ Lub sijhawm pabcuam tuav lub hom phiaj tseem ceeb ntawm kev lav phib xaub rau txhua tus neeg siv khoom muab cov ntaub ntawv qhia txog lub sijhawm los ntawm kev txiav txim kom xa cov tshuab.

| Qauv | LB-100 | LB-300 | LB-500 |

| Dav ntawm Profile (mm) | 100 | 300 | 500 |

| Ntsia Hlau Qauv | 55/110 ib | 65/132 ib | 80/156 ib |

| Peev xwm (kg / h) | 150 | 250 | 400 |