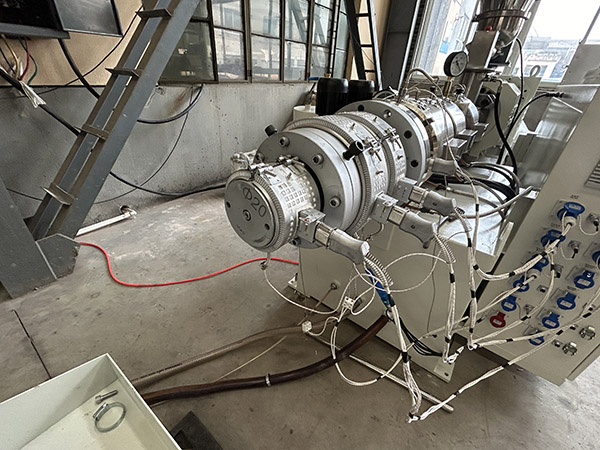

Vim yog cov yam ntxwv ntawm cpvc raw khoom, cov ntsia hlau, chim, tuag pwm, haul-off thiab cutter tsim txawv ntawm upvc yeeb nkab extrusion kab.

Niaj hnub no cia peb tsom mus rau cov ntsia hlau thiab tuag pwm tsim.

Yuav ua li cas hloov cov ntsia hlau tsim rau cpvc yeeb nkab extrusion

Hloov kho cov ntsia hlau tsim rau CPVC yeeb nkab extrusion suav nrog kev hloov kho kom zoo dua melting, sib tov, thiab xa cov khoom siv CPVC. Nov yog qee qhov kev txiav txim siab rau kev hloov kho cov ntsia hlau tsim:

1. ** Screw Geometry **:

- Hloov kho lub davhlau qhov tob thiab suab: Kho lub davhlau qhov tob thiab suab tuaj yeem txhim kho kev xa khoom thiab sib xyaw ntawm CPVC cov khoom hauv cov ntsia hlau channel.

2. **Compression Ratio**:

- Ua kom qhov sib piv compression: CPVC qhov ntau dua yaj viscosity yuav xav tau ntau dua compression piv los tsim kom txaus siab thiab shear rau melting thiab sib tov.

3. ** Ntsia Hlau Khoom thiab Txheej **:

- Siv cov ntaub ntawv lossis txheej txheej nrog txhim kho hnav tsis kam thiab tiv thaiv corrosion kom tiv taus qhov abrasive thiab corrosive xwm ntawm CPVC ua.

- Xav txog cov txheej txheem los yog kev kho mob uas txo cov kev sib txhuam thiab txhim kho cov khoom tso tawm los txhim kho CPVC yaj ntws thiab txo cov ntsia hlau hnav.

4. **Screw Cooling/Heating**:

- Siv cov cua sov / cua txias ntawm cov ntsia hlau chim los tswj cov kub thiab viscosity, tshwj xeeb tshaj yog nyob rau hauv cov cheeb tsam uas CPVC yuav muaj thermal degradation los yog overheating.

5. ** Ntsia Hlau Txias **:

- Ua kom cov ntsia hlau txias kom zoo kom tswj tau qhov kub thiab txias ntawm CPVC yaj, tshwj xeeb tshaj yog nyob rau hauv cov txheej txheem kub ceev extrusion.

Los ntawm kev txiav txim siab txog cov xwm txheej no thiab ua kom tsim nyog hloov kho rau cov ntsia hlau tsim, cov tuam txhab tuaj yeem txhim kho CPVC yeeb nkab extrusion txheej txheem kom ua tau raws li qhov zoo sib xws, homogeneity, thiab dhau los.

Yuav ua li cas hloov qhov tuag tsim rau cpvc yeeb nkab extrusion

Kev hloov kho qhov tuag tsim rau CPVC yeeb nkab extrusion suav nrog kev hloov kho kom haum rau CPVC qhov siab dua yaj viscosity thiab xyuas kom meej extrusion.

1. **Tuag cua sov / txias **:

- Kho qhov cua sov / cua txias: CPVC qhov kub ua haujlwm ntau dua yuav xav tau kev hloov kho rau cov cua sov tuag / cua txias kom tswj tau qhov kub thiab txias kom tsis txhob muaj cua sov lossis cua txias.

2. **Cov khoom siv tuag thiab coatings**:

- Xav txog kev siv cov ntaub ntawv / txheej nrog cov cua sov siab dua: CPVC qhov kub ua haujlwm ntau dua yuav xav tau cov ntaub ntawv tuag lossis cov txheej txheem uas tuaj yeem tiv taus qhov kub siab yam tsis muaj degradation.

3. ** Tuag Nto Ua tiav **:

- Ua kom lub ntsej muag du thiab zoo sib xws: Lub npoo tuag du pab txo qis kev sib txhuam thiab shear rog, txo qhov kev pheej hmoo ntawm cov pob txha tawg thiab ua kom muaj kev sib xyaw ua ke.

4. **Flow Control Devices**:

- Koom nrog cov khoom siv tswj kev khiav dej num, xws li cov ntawv ntxig lossis cov txwv, txhawm rau txhim kho kev faib tawm thiab siab sib xws thoob plaws qhov profile tuag, tshwj xeeb tshaj yog nyob rau hauv cov kab zauv tuag.

5. ** Tuag Tsim Simulation**:

- Siv cov qauv tsim simulation software txhawm rau txheeb xyuas tus cwj pwm ntws, kev faib tawm siab, thiab qhov ntsuas kub hauv qhov tuag. Qhov no tso cai rau kev sim virtual ntawm ntau yam kev hloov pauv tuag los ua kom zoo dua ua ntej siv lub cev.

Los ntawm kev txiav txim siab txog cov xwm txheej no thiab ua qhov kev hloov kho tsim nyog rau kev tsim qauv tuag, cov tuam ntxhab tuaj yeem ua kom zoo dua CPVC yeeb nkab extrusion txheej txheem kom ua tiav qhov zoo ib yam thiab qhov tseeb.

Nyob rau hauv cov txheej txheem extrusion ntawm cpvc yeeb nkab, uas cov ntsiab lus yuav tsum tau ceev faj

Thaum lub sij hawm extrusion txheej txheem ntawm CPVC (Chlorinated Polyvinyl Chloride) kav, ob peb lub ntsiab lus yuav tsum tau ceev faj saib xyuas kom cov zus tau tej cov kav dej zoo. Nov yog qee cov ntsiab lus tseem ceeb:

1. ** Khoom siv thiab sib tov **:

- Xyuas kom raug tuav thiab sib tov ntawm CPVC resin thiab additives kom ua tau zoo dispersion thiab sib xws ntawm cov khoom. Kev sib xyaw kom zoo yog qhov tseem ceeb rau kev tswj xyuas cov khoom xav tau ntawm CPVC compound.

2. ** Kev tswj qhov kub thiab txias **:

- Saib xyuas thiab tswj qhov kub ntawm extrusion ua tib zoo, raws li cov khoom siv CPVC muaj qhov kub thiab txias rau kev ua haujlwm. Khaws qhov kub thiab txias nyob rau hauv qhov kev pom zoo kom tiv thaiv kom tsis txhob degradation ntawm cov khoom thiab xyuas kom meej yaj txaus.

3. **Screw Design thiab Configuration**:

- Siv cov ntsia hlau extruder tsim tshwj xeeb rau kev ua cov khoom siv CPVC. Cov ntsia hlau tsim yuav tsum muab kev sib xyaw kom txaus thiab homogenization ntawm cov yaj thaum txo qis shear cua sov kom tsis txhob muaj cov khoom degradation.

4. **Tuag Tsim thiab Calibration**:

- Xyuas kom cov qauv tuag tsim nyog rau CPVC yeeb nkab extrusion, nrog rau qhov ntev thiab geometry los tsim cov kav dej nrog cov phab ntsa tuab thiab txoj kab uas hla. Calibrate qhov tuag kom ua tiav cov yeeb nkab ntev.

5. ** Txias thiab quenching **:

- Siv cov tshuab ua kom txias thiab quenching kom ceev cov yeeb nkab CPVC extruded thiab teeb nws qhov ntev. Kev ua kom txias kom zoo yog qhov tseem ceeb rau kev tiv thaiv warping lossis distortion ntawm cov yeeb nkab thiab ua kom muaj qhov ruaj khov.

6. ** Rub thiab Sizing **:

- Tswj qhov rub nrawm thiab qhov loj me ntawm CPVC yeeb nkab kom ua tiav qhov xav tau qhov ntev thiab qhov chaw tiav. Kev rub thiab sizing kom zoo ib yam ntawm cov yeeb nkab txoj kab uas hla thiab phab ntsa thickness thoob plaws qhov ntev ntawm cov yeeb nkab.

7. **Kev Saib Xyuas thiab Kev Tswj Xyuas Zoo**:

- Siv kev saib xyuas zoo thiab tswj hwm zoo los kuaj xyuas cov tsis xws lossis tsis sib xws hauv cov kab mob CPVC kav. Ua cov kev tshuaj xyuas thiab kev ntsuam xyuas tsis tu ncua kom ntseeg tau tias ua tau raws li cov kev qhia tshwj xeeb thiab cov qauv.

Los ntawm kev ua tib zoo tswj cov ntsiab lus no thaum lub sij hawm extrusion txheej txheem, manufacturers muaj peev xwm tsim tau zoo CPVC kav uas ua tau raws li qhov yuav tsum tau specifications thiab cov qauv kev ua tau zoo.

Post lub sij hawm: Apr-02-2024