01 Mechanical txoj cai

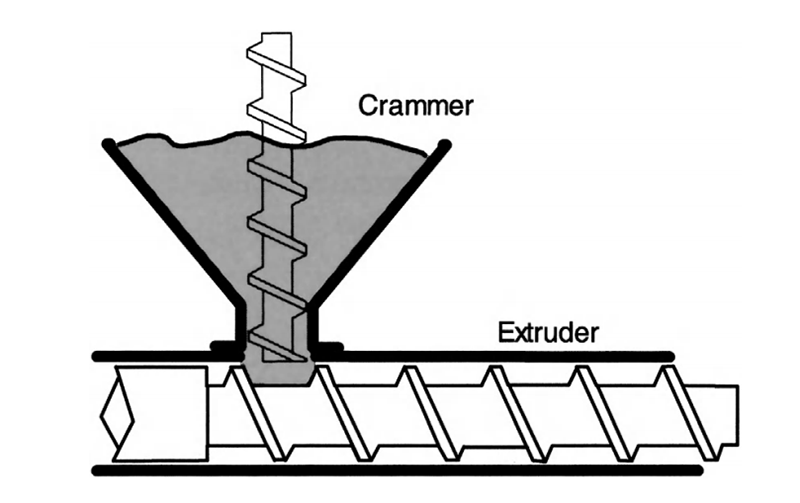

Lub hauv paus txheej txheem ntawm extrusion yog yooj yim - ib tug ntsia hlau tig rau hauv lub tog raj kheej thiab thawb cov yas rau pem hauv ntej. Cov ntsia hlau tiag tiag yog ib qho bevel lossis ramp uas raug mob nyob ib ncig ntawm lub hauv paus txheej. Lub hom phiaj yog txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau kov yeej kev tawm tsam ntau dua. Nyob rau hauv cov ntaub ntawv ntawm ib tug extruder, muaj 3 hom kev tiv thaiv kom kov yeej: kev sib txhuam ntawm cov khoom siv (pub) ntawm lub tog raj kheej phab ntsa thiab kev sib nrig sib txhuam ntawm lawv thaum cov ntsia hlau tig ob peb lem (chaw noj); adhesion ntawm yaj mus rau lub tog raj kheej phab ntsa; Kev tiv thaiv ntawm yaj mus rau nws cov logistics sab hauv thaum nws raug thawb rau pem hauv ntej.

Feem ntau cov ntsia hlau ib leeg yog txoj cai xov, zoo li cov siv hauv kev ua ntoo thiab tshuab. Yog saib tom qab, lawv tab tom tig rov qab vim lawv ua qhov zoo tshaj plaws los tig lub thoob rov qab. Hauv qee qhov ntxaib ntsia hlau extruders, ob lub hau ntswj tig rov qab rau hauv ob lub tog raj kheej thiab hla ib leeg, yog li ib qho yuav tsum tig sab xis thiab lwm qhov yuav tsum tig sab laug. Nyob rau hauv lwm qhov tom ntxaib screws, ob lub hau ntswj tig nyob rau hauv tib txoj kev thiab yog li yuav tsum muaj tib txoj kev taw qhia. Txawm li cas los xij, nyob rau hauv ob qho tib si, muaj cov kabmob thrust uas nqus rov qab zog, thiab Newton txoj cai tseem siv tau.

02 Thermal txoj cai

Extrudable plastics yog cov thermoplastics – lawv yaj thaum rhuab thiab solidify dua thaum txias. Lub tshav kub ntawm cov yas yaj tuaj qhov twg? Pub preheating thiab lub tog raj kheej / tuag lub tshuab cua sov tuaj yeem ua haujlwm thiab tseem ceeb ntawm kev pib, tab sis lub cev muaj zog input zog-kev sib txhuam ntawm lub tog raj kheej thaum lub cev muaj zog tig lub hau ntswj tawm tsam qhov tsis kam ntawm cov kua nplaum-yog qhov tseem ceeb tshaj plaws ntawm cov cua sov. rau tag nrho cov yas, tshwj tsis yog rau cov tshuab me me, cov ntsia hlau tsis tshua muaj siab, cov yas kub yaj hauv siab, thiab cov ntawv thov txheej extrusion.

Rau tag nrho lwm yam kev ua haujlwm, nws yog ib qho tseem ceeb kom paub tias lub tshuab rhaub cartridge tsis yog lub hauv paus cua sov hauv kev ua haujlwm thiab yog li ntawd muaj kev cuam tshuam tsawg dua ntawm extrusion dua li peb xav tau. Qhov kub ntawm lub tog raj kheej sab nraub qaum kuj tseem yog qhov tseem ceeb vim tias nws cuam tshuam rau tus nqi ntawm cov khib nyiab thauj hauv meshing lossis pub. Kev tuag thiab pwm kub yuav tsum feem ntau yog qhov xav tau melting kub los yog ze rau nws, tshwj tsis yog tias lawv tau siv rau lub hom phiaj tshwj xeeb xws li varnishing, dej faib, lossis tswj siab.

03 Deceleration txoj cai

Nyob rau hauv feem ntau extruders, qhov kev hloov ntawm cov ntsia hlau ceev yog tiav los ntawm kev kho lub cev muaj zog ceev. Lub cev muaj zog feem ntau tig ntawm qhov nrawm ntawm li 1750rpm, tab sis qhov ntawd nrawm dhau rau ib qho extruder ntsia hlau. Yog hais tias nws yog rotated nyob rau hauv xws li ib tug ceev ceev, ntau heev sib sib zog nqus tshav kub yog generated, thiab lub sij hawm nyob rau hauv cov yas yog luv heev los npaj ib tug uniform, zoo-stirred yaj. Qhov piv txwv ntawm kev txo qis yog nyob nruab nrab ntawm 10: 1 thiab 20: 1. Thawj theem tuaj yeem yog geared lossis pulley, tab sis theem ob yog geared thiab cov ntsia hlau yog nyob rau hauv nruab nrab ntawm lub xeem loj iav.

Hauv qee lub tshuab ua haujlwm qeeb (xws li ntxaib ntsia hlau rau UPVC), tej zaum yuav muaj 3 theem deceleration thiab qhov siab tshaj plaws ceev yuav qis li 30 rpm lossis tsawg dua (qhov sib piv txog 60: 1). Nyob rau lwm yam huab, qee qhov ntev ntxaib ntsia hlau rau nplawm tuaj yeem khiav ntawm 600rpm lossis sai dua, yog li yuav tsum muaj tus nqi qis heev thiab ntau qhov txias txias.

Qee lub sij hawm tus nqi deceleration yog mismatched rau txoj hauj lwm - lub zog ntau dhau lawm tsis siv - thiab nws muaj peev xwm ntxiv ib lub pulley teem ntawm lub cev muaj zog thiab thawj deceleration theem uas hloov lub siab tshaj plaws ceev. Qhov no yog ua kom cov ntsia hlau ceev tshaj qhov kev txwv dhau los lossis txo qhov siab tshaj plaws, cia lub kaw lus ua haujlwm ntawm qhov feem pua ntawm qhov siab tshaj plaws. Qhov no ua rau kom lub zog muaj zog, txo cov amperage thiab zam teeb meem lub cev muaj zog. Hauv ob qho tib si, cov zis tuaj yeem nce ntxiv nyob ntawm cov khoom siv thiab nws cov kev xav tau cua txias.

Xovxwm tiv tauj:

Qing Hu

Langbo Machinery Co., Ltd

No.99 Lefeng Road

215624 Leyu lub zos Zhangjiagang Jiangsu

Xov tooj: +86 58578311

EMail: info@langbochina.com

Web: www.langbochina.com

Post lub sij hawm: Jan-17-2023